Steamed Beech

Steamed Beech Specification

- Core Material

- Solid Beech

- Formaldehyde Emission Standards

- E1

- Load Capacity

- High

- Wood Type

- Steamed Beech

- Density

- 900 Gram per cubic centimeter(g/cm3)

- Thickness

- 25 mm, 38 mm, 50 mm, Customizable

- Tolerance

- 1 mm

- Surface Treatment

- Kiln Dried, Steamed

- Moisture Content

- 8-12%

- Finish Type

- Smooth Finish

- Product Type

- Steamed Beech Wood

- Timber Type

- Hardwood

- Usage

- Furniture, Flooring, Interior Joinery, Paneling

- Grade

- A, AB, B

- Size

- As per customer requirement

- Feature

- Durable, High Strength, Good Workability

- Shape

- Rectangular, Planks

- Splitting Resistance

- Good

- Color

- Light to Pinkish Brown

- Edge Type

- Square

- Bending Strength

- High

- Odor

- Faint, mild wood scent

- Environmental Compliance

- Complies with international timber standards

- Workability

- Excellent for machining and finishing

- Seasoning

- Properly seasoned to reduce warping

- Application

- Cabinets, Doors, Handrails

- Janka Hardness

- 1,450 lbf

- Storage Recommendations

- Store in dry, covered areas

- Custom Sizing

- Available on request

- Availability

- Readily Available

Steamed Beech Trade Information

- Minimum Order Quantity

- 5 Feet

- Supply Ability

- 2000 Feet Per Week

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About Steamed Beech

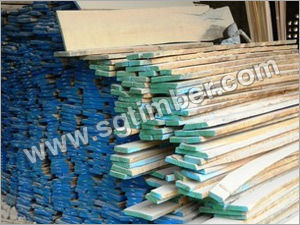

To meet the diversified requirements of our esteemed patrons, we are manufacturing, exporting and supplying a wide gamut of Steam Beach wood. The offered beach wood is cut and finished under the guidance of our experienced professionals with the help of avant-garde techniques. This beach is widely used for flooring and paneling purpose. Moreover, our patrons can avail the offered Steam Beach at highly affordable prices from us.

Features:

-

Sturdiness

-

High strength

-

Superior finish

-

Moisture resistance

Premium Hardwood for Impeccable Interiors

Steamed Beech delivers exceptional strength and durability, making it a reliable choice for both residential and commercial interiors. Its beautiful, light to pinkish brown appearance suits a variety of design styles, from modern to traditional. Thanks to its high bending strength and resistance to splitting, this hardwood ensures the stability and longevity of finished products. Our Steamed Beech is available with customizable sizing, offering flexibility for any project.

Superior Workability and Smooth Finish

Known for its excellent machining and finishing properties, Steamed Beech is preferred by woodworkers and manufacturers. The timber is kiln dried and finely steamed, resulting in a product that is easier to handle and less prone to warping. The surface treatment guarantees a consistently smooth finish, enhancing the natural beauty of the wood while ensuring its adaptability for furniture, doors, and paneling.

Sustainable Sourcing and Quality Assurance

Our Steamed Beech complies with international timber and environmental standards, supporting responsible sourcing and manufacturing. With low formaldehyde emissions (E1 standard) and thorough seasoning, the timber aligns with sustainability and safety benchmarks. Each batch is graded (A, AB, B) and rigorously tested to meet density, moisture, and tolerance requirements, ensuring consistent quality for every customer.

FAQs of Steamed Beech:

Q: How should Steamed Beech timber be stored to maintain its quality?

A: Steamed Beech should be stored in dry, covered areas to safeguard against moisture and prevent warping. It is recommended to keep the wood elevated from the ground and away from direct sunlight for best preservation.Q: What applications can Steamed Beech be used for?

A: This hardwood is suitable for a diverse range of applications, including cabinets, doors, handrails, furniture, flooring, interior joinery, and paneling. Its strength and smooth finish make it popular for both structural and aesthetic uses.Q: When is Steamed Beech the preferred choice for interior woodwork?

A: Steamed Beech is chosen when durability, high load capacity, and a uniform, attractive appearance are priorities. Its excellent machinability and finishing make it ideal for custom and high-precision woodwork.Q: Where is your Steamed Beech sourced and supplied?

A: Our Steamed Beech is distributed, exported, imported, and supplied across India by reputable manufacturers and traders, ensuring consistent quality and availability.Q: What is the process for customizing Steamed Beech sizes and thicknesses?

A: Clients can request custom sizes and thicknessesincluding 25mm, 38mm, 50mm, or as required. Each order is prepared with precise tolerance (1 mm) and processed through kiln drying and steaming to ensure quality and stability.Q: How does Steamed Beech benefit furniture makers and interior designers?

A: Its high strength, good splitting resistance, and excellent workability make manufacturing easier, while the smooth, attractive finish enhances aesthetic appeal. Designers value its adaptability and the minimal, pleasant wood scent.Q: What environmental and safety standards does Steamed Beech meet?

A: This timber complies with international environmental and formaldehyde emission standards (E1) and is sourced through sustainable practices, making it a safe and responsible choice for interior projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steam Beech Wood Category

Steamed Beech Timber

Price Range 1000.00 - 2000.00 INR / Foot

Minimum Order Quantity : 5 Feet

Grade : A, AB, B grades available

Shape : Rectangular planks, boards, squares

Load Capacity : Dependent on dimensions and structural application

Size : Custom sizes available, standard lengths 616 ft

Steam Beech Wood Timber

Price Range 1000.00 - 2000.00 INR / Foot

Minimum Order Quantity : 5 Feet

Grade : A/B Grade (Premium, Select)

Shape : Rectangular Planks

Load Capacity : High loadbearing capacity, ideal for structural and furniture applications

Size : Available in various sizes (customizable as per requirement)

Steam Beech Wood Moulding

Price Range 1000.00 - 2000.00 INR / Foot

Minimum Order Quantity : 5 Feet

Grade : A/B (Select grade, knotfree, uniform texture)

Shape : Rectangular, Sshaped, Ogee, custom profiles available

Load Capacity : Suitable for light to medium structural applications

Size : Custom sizes available; standard lengths from 6 to 12 feet

Beech Wood Timber

Price Range 1000.00 - 2000.00 INR / Foot

Minimum Order Quantity : 5 Feet

Grade : AB Klin Dried

GST : 07AEUPG2921G1ZH

|

|

S G TIMBER

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry