Steamed Beech Timber

Steamed Beech Timber Specification

- Wood Type

- Hardwood

- Thickness

- 25mm, 38mm, 50mm, or as per requirement

- Core Material

- Solid Beech Wood

- Tolerance

- +/- 1 mm

- Load Capacity

- Dependent on dimensions and structural application

- Finish Type

- Raw / Unfinished

- Glue

- Not applicable (solid wood)

- Density

- 720 Gram per cubic centimeter(g/cm3)

- Formaldehyde Emission Standards

- E1 (Low emission)

- Moisture Content

- 8-12% (kiln dried)

- Surface Treatment

- Steamed and Kiln Dried

- Product Type

- Hardwood Timber

- Timber Type

- Steamed Beech

- Usage

- Furniture Making, Interior Applications, Joinery, Cabinetry, Flooring, Decorative Veneer

- Grade

- A, AB, B grades available

- Size

- Custom sizes available, standard lengths 6-16 ft

- Feature

- High strength, Uniform texture, Good stability, Easy to work with, Smooth surface finish

- Shape

- Rectangular planks, boards, squares

- Workability

- Easily stained, polished, glued and finished

- Environmental Certification

- FSC or PEFC available on request

- Fire Resistance

- No special fire resistance treatment

- Machinability

- Excellent

- Color

- Pale pinkish-brown to reddish-brown

- Janka Hardness

- 1,450 lbf (6,450 N)

- Shrinkage

- Medium

- Storage Recommendation

- Store in dry, covered, well-ventilated area

- Heartwood/Sapwood

- Limited color difference, usually homogeneous

- Durability

- Moderate (non-durable to fungi)

- Application Standards

- Conforms to EN 942 for joinery quality hardwoods

- Absorption Rate

- Moderate

- Seasoning

- Kiln dried and steamed to prevent warping

- Edge Profile Options

- Square, rounded, custom profiles on request

Steamed Beech Timber Trade Information

- Minimum Order Quantity

- 5 Feet

- Supply Ability

- 2000 Feet Per Week

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About Steamed Beech Timber

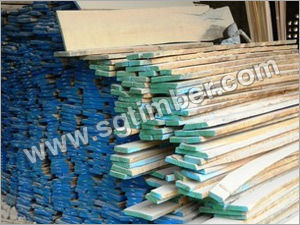

Steamed Beech Timber

As a reckoned entity, we are manufacturing, exporting and supplying an exclusive range of Steamed Beech Timber. The offered timber is mainly used for furniture making and interior works. This timber is cut and finished by our diligent professionals with the aid of pioneering techniques at our well-developed processing unit. Besides, our clients can avail the offered Steamed Beech Timber in various sizes at the most economical rates.

Feature:

- Optimum strength

- Impact resistance

- Light weight

- Free from termite

Superior Surface and Machinability

Steamed Beech Timber features a consistently smooth finish, thanks to precise kiln drying and steaming processes. Its homogeneous color, limited heartwood-sapwood difference, and fine, uniform texture make it exceptionally easy to machine, stain, polish, glue, and finish. With custom edge profiles available, its tailored for sophisticated woodworking projects.

Durability and Environmental Responsibility

While Steamed Beech is moderately durable (non-durable to fungi), kiln drying enhances its dimensional stability. Available with FSC or PEFC certification, this timber meets global standards for sustainable forestry. It also adheres to EN 942 specifications for joinery-quality hardwoods and maintains low formaldehyde emissions (E1), ensuring safety and quality in every application.

Versatile Application and Custom Sizing

Ideal for furniture making, interior joinery, cabinetry, decorative veneer, and flooring, Steamed Beech Timber supports both standard and custom size requirements. With standard lengths of 6-16 ft and thickness options from 25mm up to 50mm or as needed, it provides flexibility for a wide range of design concepts and structural needs.

FAQs of Steamed Beech Timber:

Q: How is Steamed Beech Timber seasoned to prevent warping and ensure stability?

A: Steamed Beech Timber undergoes a combination of kiln drying and steaming processes. This carefully controlled seasoning reduces moisture content to 8-12%, minimizing the risk of warping, cracking, or distortion and promoting excellent dimensional stability.Q: What makes Steamed Beech Timber suitable for furniture and joinery applications?

A: Its uniform texture, high strength, smooth finish, and excellent machinability make Steamed Beech ideal for crafting furniture, cabinetry, and interior joinery. The timber is easy to cut, shape, stain, and polish, resulting in high-quality finished products.Q: When should I choose Steamed Beech Timber over other hardwoods?

A: Choose Steamed Beech Timber when you require homogeneous color, a smooth surface, reliable dimensional stability, and a material that works well with finishing techniques. Its especially recommended for projects conforming to EN 942 joinery standards or where FSC/PEFC certification is needed.Q: Where is Steamed Beech Timber typically used?

A: This timber is commonly used in furniture manufacturing, cabinetry, flooring, interior joinery, decorative veneers, and other interior applications. It is distributed, exported, and supplied across India and meets stringent quality standards for these uses.Q: What are the recommended storage conditions for Steamed Beech Timber?

A: To preserve its quality, store Steamed Beech Timber in a dry, covered, and well-ventilated area. Proper storage prevents moisture absorption, fungal growth, and other issues that might compromise its strength and appearance.Q: How does the formaldehyde emission level of Steamed Beech Timber benefit users?

A: Steamed Beech Timber conforms to E1 emission standards, meaning it has low formaldehyde emissions. This ensures better indoor air quality and safety for users, particularly in residential and commercial interior applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steam Beech Wood Category

Steam Beech Wood Moulding

Price Range 1000.00 - 2000.00 INR / Foot

Minimum Order Quantity : 5 Feet

Grade : A/B (Select grade, knotfree, uniform texture)

Shape : Rectangular, Sshaped, Ogee, custom profiles available

Core Material : Steam Beech Wood

Tolerance : 1 mm

Steam Beech Wood Timber

Price Range 1000.00 - 2000.00 INR / Foot

Minimum Order Quantity : 5 Feet

Grade : A/B Grade (Premium, Select)

Shape : Rectangular Planks

Core Material : Beech Wood

Tolerance : 0.5mm

Steamed Beech

Price Range 1000.00 - 2000.00 INR / Foot

Minimum Order Quantity : 5 Feet

Grade : A, AB, B

Shape : Rectangular, Planks

Core Material : Solid Beech

Tolerance : 1 mm

Beech Wood Timber

Price Range 1000.00 - 2000.00 INR / Foot

Minimum Order Quantity : 5 Feet

Grade : AB Klin Dried

GST : 07AEUPG2921G1ZH

|

|

S G TIMBER

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry